THURSDAY, APRIL 7, 2022

Researchers from the University of Illinois Chicago recently announced that they have developed environmentally safe, frost-resistant coatings for the aerospace industry.

The study, authored by Sushant Anand, UIC assistant professor of mechanical engineering, and Rukmava Chatterjee, a UIC PhD student, was recently published in Advanced Materials.

About the Coatings

Wanting to make a more efficient product for airplane deicing, Anand and Chatterjee looked at developing a longer-lasting alternative to conventional deicers. Additionally, the team noted that most of the traditional deicing fluids is gone from the surface of the aircraft before it takes off, polluting freshwater streams and lakes.

“We questioned the lifetime of the cryoprotectants and looked at new ways to increase their effectivity,” Anand said. “Glycols dissolve very fast in the water and get washed away before the plane takes off, and it’s a serious problem that costs hundreds of millions of dollars – most of which literally ends up in the drain.

“We thought, why not improve such chemicals themselves, and make alternatives that can last longer while being more biofriendly. And that is what we ended up doing.”

|

| Sushant Anand and Rukmava Chatterjee |

|

Researchers from the University of Illinois Chicago recently announced that they have developed environmentally safe, frost-resistant coatings for the aerospace industry. |

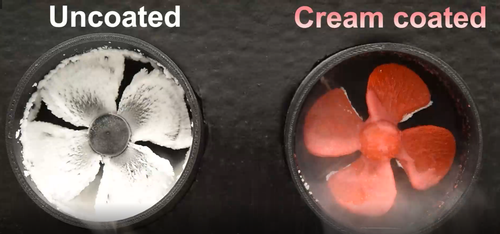

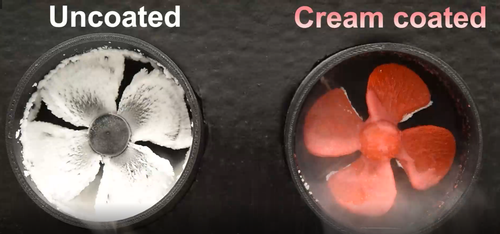

According to UIC, to accomplish their goal, the team developed a family of more than 80 anti-freezing coatings, which can be classified as polymeric solutions, emulsions, creams and gels. Without preconditioning or surface treatments, these formulations can reportedly be applied to aluminum, steel, copper, glass, plastic or other industrial surfaces.

“Our coatings are an all-in-one package which can delay formation of frost for extended hours and simultaneously cause any ice formed on its surface to easily shed off by a gentle breeze or simple substrate tilting,” Chatterjee said.

UIC reports that the coatings are a family of phase change material-based formulations and multifunctional coatings, tailored for solid foulant adhesion on functional surfaces. This ranges from ice to bacteria, regardless of their inherent material structure and chemistry.

The researchers reportedly engineered the coatings by regulating how chemicals leach out of the material system and by creating a lubricating surface layer that is both slippery and non-freezing in nature. The gels are also transparent, allowing for applications on traffic signals, runway lights, automotive windshields or building windows.

“Imagine coating your smartwatch with our gel that can inhibit ice accretion in the chilly negatives while simultaneously preventing any bacterial contamination,” Chatterjee said.

“Since our anti-icing sprays are bio-friendly and anti-bacterial, we even think there is a potential to use them in agriculture to prevent crops from being ruined by severe frost,” Anand said. “But that is a pipe dream, and we need to do more studies to see if there will be any long-term adverse effect on the plants.”

Anand Research Group members Hassan Bararnia and Umesh Chaudhuri collaborated with Chatterjee on the experiments. UIC reports that a worldwide patent application titled “Compositions and Methods for Inhibiting Ice Formation on Surfaces” has been filed by its Office of Technology Management.

“There is great potential in these materials for many applications, and I think the day when commercial versions of our materials come out just got closer,” Anand said.

Recent Icephobic Coatings

In November, Zentek Ltd., a Canadian development and commercialization company, announced the development of its new carbon-based, nanotechnology-enhanced icephobic coating.

Tests for adhesion strength required to dislodge ice from surfaces were conducted with a third-party lab, with the coating reportedly demonstrating an adhesion strength consistently around 20 kilopascals. Zentek reported at the time that the typical ice adhesion strength of a bare aluminum alloy is about 500 kilopascals, while a classified icephobic surface must be less than 100 kilopascals, with the coating having a 96% improvement over aluminum and 80% improvement over the 100 kPa threshold.

Last month, the company reported the “excellent” results of testing conducted on its icephobic coating. These tests included real-world testing, drone testing and accelerated age testing.

The next rounds of testing will include testing the coating for sand and rain erosion. Zentek reports that it is also planning tests to evaluate the coating as part of a hybrid ice protection system alongside a heated deicing system to improve efficiency.

According to the company, these tests are already scheduled and results will be reported once they are available.

Also last month, researchers from the Institute for Materials Discovery at the University College London were reported to have developed a nanocomposite-based, superhydrophobic coating designed to limit ice formation in industrial applications.

According to the study, developing superhydrophobic or icephobic coatings is significant in limiting ice formation. The team notes that recent investigations focus on scientific research, but not practical application.

To solve this, the team designed and fabricated nanocomposite-based superhydrophobic PVDF-HFP/SiO2/CNTs coatings. These coatings reportedly exhibited “exceptional” water repellency at a contact angle up to 168 degrees and slide angle lower than 2 degrees.

The anti-icing performance of the coatings was “excellent,” with ice formation on aluminum film delayed by more than 300 seconds at -19 C. Researchers created equipment designed to investigate the placement orientation of the coated sample’s anti-icing performance.

Additionally, the nanocomposite coating reportedly has “superior” deicing characteristics, with ice adhesion strength testing lower than 10kPa so that it can be detached naturally from wind or its own weight.

In January, a research team from the Skolkovo Institute of Science and Technology (Skoltech) in Moscow tested hydrophobic coatings and their effectiveness combined with other anti-icing systems.

Researchers at Skoltech then decided to test the surface wettability of aluminum in aircraft skin and see if it affects the performance of these fluids.

Three different types of fluids, which satisfied aerospace standards SAE AMS1424 or AMS1428, were tested. Each fluid type, including Type I, II and IV had different endurance times. Aluminum plates were sanded, polished and coated with a hydrophilic transparent, glossy or matte acrylic varnish.

In contrast to a Canadian team’s findings, they discovered that plate wettability had no impact on the performance of anti-icing fluids, but attribute this finding to the surface tension and viscosity of anti-icing fluids. Researchers also noted that surface roughness could play a role, since rough surfaces take longer to accumulate ice.

According to Skoltech, the study showed that the accumulation of liquid in the surface texture reduces the water-repellent properties of hydrophobic coatings.

Tagged categories: Aerospace; aircraft; Antibacterial coatings; Coating Materials; Coatings; Colleges and Universities; Environmental Controls; Gel; Green coatings; icephobic; Industrial coatings; Polymers; Program/Project Management; Research; Research and development