WEDNESDAY, FEBRUARY 2, 2022

Research groups from Rice University and the Kuwait Institute for Scientific Research recently developed a new technique to identify concrete fractures typically invisible to the naked eye.

The study, which was published in Scientific Reports, was lead by Rice chemist Bruce Weisman, Rice structural engineer Satish Nagarajaiah and Kuwait Institute investigator Jafarali Parol, and coauthored by Rice research scientist Sergei Bachilo and original author Wei Mang. The research was supported by the Kuwait Institute for Scientific Research and the National Science Foundation.

“This arose from a project in which we were trying to apply our strain measurement technique to cement and concrete, but we ran into an unexpected problem when we illuminated a specimen coated with a nanotube film,” said Weisman, a pioneer in nanotube spectroscopy. “We found that one of the peaks in our film spectrum was obscured by much stronger emission coming from somewhere. We never expected it would be from the cement itself.

“Eventually, we were able to mask off the specimen so the emission didn’t interfere with our strain measurement. But we kept in the backs of our minds that maybe this could be interesting on its own.”

The scientists discovered that the silicon crystals in Portland cement emit fluorescent, infrared light. According to the release, the researchers realized that the exact wavelength of the emission can be used to identify the particular type of cement in a structure, but also that, when painted with a thin coat of opaque paint, the small cracks glow under near-infrared light.

|

| Rice University |

|

Research groups from Rice University and the Kuwait Institute for Scientific Research recently developed a new technique to identify concrete fractures typically invisible to the naked eye. |

“Minerals called silicates are major components of cement, and we hypothesized that during the high temperature production process, very small amounts decompose to form microscopic silicon crystals,” Weisman said. “Their emission wavelength tells us that they’re larger than about 10 nanometers, but they can’t be much bigger or people would have noticed them long ago.”

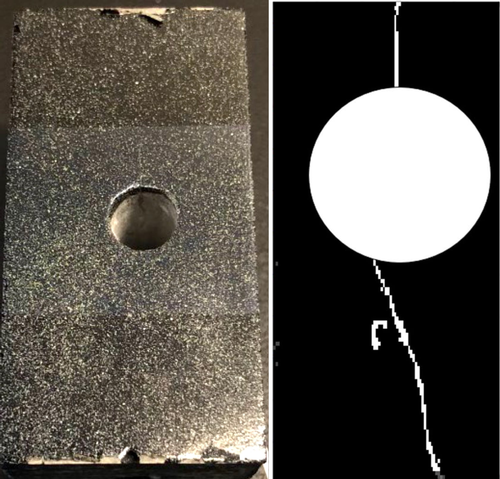

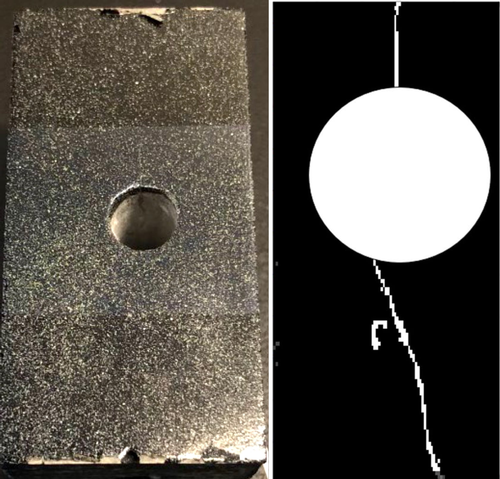

To test this, Meng used small concrete blocks painted black with holes drilled in the middle. Three commercial Portland cements were used for the experiment:

The drilled holes served as focal points to form microcracks, moving outward during compression, which also cracked the paint. The fluorescent signal was then shown through the cracks and mapped with a raster-scanning laser. The intact concrete appeared black, while the glowing light showed the cracks.

Additionally, the researchers found that the spectrum level was not affected by hydration level, testing different water-to-cement ratios and how long the cement blocks cured.

“Concrete structures need monitoring, and this is one way of monitoring them,” said Nagarajaiah, who specializes in infrastructure/structural monitoring, system identification, damage detection and adaptive stiffness structure systems to withstand seismic events. “Getting a clear idea of where cracks are can be quite important in structures, especially in the critical places where we know they’re going to be stressed.”

Nagarajaiah added that the benefits of better crack detection could extend beyond bridges and buildings to containment structures at nuclear power plants, on ships or inside wells and pipelines that are difficult to access. One practical approach would be to shine light on these structures, then photograph them with a near-infrared camera and narrow-band spectral filter.

“Cement cracking can be an early symptom of failure, so people who are concerned with the structural integrity and safety of concrete structures want to detect microcracks before they grow,” Weisman said.

Recent Concrete Fracture Research

Last month, researchers from China proposed a new method for analyzing cracks in plain concrete linings using the double-K fracture criterion. The study, which was recently published in Applied Sciences, was conducted by the Shanghai Jiao Tong University, Shanghai Marine Diesel Engine Research Institute and the China Academy of Transportation Sciences.

According to the study, cracks, leakage, spalling and displacements are the main indications of anomalies that affect the stability of the tunnel. The lining crack is reportedly the most common and adverse anomaly, providing a key indicator of safety.

Typically, safety evaluations utilize field measurement results with empirical criteria, such as the Japan Road Association’s maintenance manual of road tunnels and maintenance technical specifications proposed by the professional standards compilation group of China. Evaluations can also use the complex variable method, fracture mechanics or damage mechanics to analyze crack resistance of the lining.

Researchers argue, however, that the prior evaluations are semi-quantitative or quantitative because they neglect the mechanical aspect of crack generation or evolution. The latter method is more quantitative, but cannot take full advantage of field measurement results, like crack width or depth.

Based on the research, the study has proposed a method that combines the fracture mechanics of concrete with the field-measured data without complicated mechanical calculations, utilizing a modified double-K fracture criterion.

For the double-K fracture criterion, the fracture process zone is reportedly equivalent to an elastic crack and the stress intensity factor is calculate by linear elastic fracture mechanics with an equivalent crack. To find these numbers, researchers measured the crack width and the load, calculated the crack depth and then calculated the stress intensity factor.

According to the study, this method introduces two parameters to evaluate the state of the cracks: initiation toughness and unstable toughness. By comparing these two factors against the stress intensity factors, the team is able to evaluate what stage of the fracture process the fracture is in.

The research team then developed a code based on the XFEM-FCM algorithm, a computational tool to detect and identify cracks in structures, to apply this method to tunnel linings and simulate the fracture process of concrete linings.

Tagged categories: Colleges and Universities; concrete; Concrete defects; Cracking; Cracks; Infrared radiation; Masonry; Program/Project Management; Research; Research and development; Silicate; Silicone