MONDAY, MAY 13, 2024

A new coating has been formulated to remain non-conductive and transparent for glass surfaces while still maintaining antimicrobial properties.

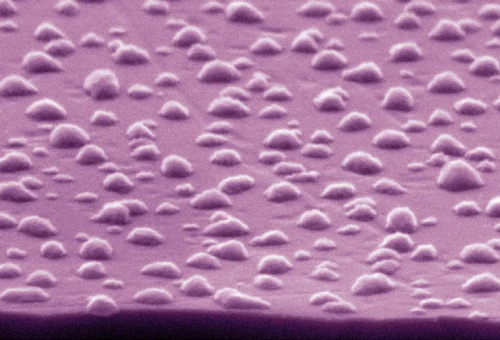

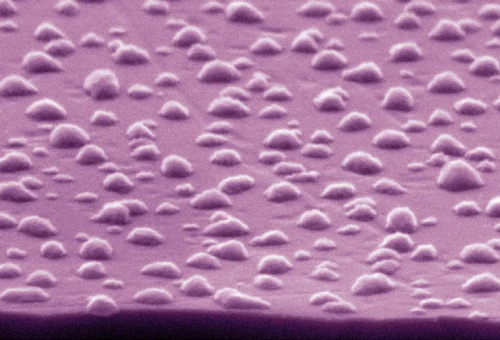

According to the research team from the Institute of Photonic Sciences (ICFO) and Corning Incorporated, the nanostructured surface was obtained by dewetting ultrathin metal copper films on a glass substrate.

The work was recently published in the journal Communications Materials.

About the Coating

ICFO says that the interest in antimicrobial solutions for personal and multi-user touch screens, such as tablets and mobile devices, has grown in recent years. However, traditional methods like sprayable alcohols or wipes are not ideal for these types of displays.

Antimicrobial coatings can be applied directly to the glass as an alternative, but only if they are transparent and long-lasting. Other proposed coating solutions, such as photocatalytic metal oxides, have posed some challenges, such as requiring light and moisture to be antimicrobial and eliminate the microbes present on the surface.

Copper is a biocidal metal with high efficacy against a wide range of microorganisms, traditionally used for objects such as door handles and hospital bedrails. However, copper coatings are mostly opaque and the electrical conductivity of the metal film can negatively interfere with touch-sensing functionality.

To find a potential solution, the team of researchers designed and implemented a transparent nanostructured copper surface (TANCS) that is non-conductive and resistant against the growth of certain bacteria.

|

| ICFO |

|

A new coating has been formulated to remain non-conductive and transparent coating for glass surfaces while still maintaining antimicrobial properties. |

According to the press release, the fabrication process involved depositing an ultra-thin copper film with a nominal thickness of 3.5nm onto a glass substrate. Then, the researchers used a rapid thermal annealing process to form dewetted Cu nanoparticles with optimal size and distribution.

The specific design and method reportedly provided an antimicrobial effect, transparency, color neutrality and electrical insulation. In a final step, additional layers of SiO2 and fluorosilanes were deposited on top of the nanoparticles to provide environmental protection and improve durability properties with use-test cases.

The researchers then examined the fabricated coating morphology, optical response, antimicrobial efficacy and mechanical durability. The TANCS reportedly showed the ability to eliminate over 99.9% of “Staphylococcus Aureus” present in the tested surfaces within two hours, under stringent dry test conditions.

Additionally, the substrate was found to demonstrate optical transparency allowing for 70% to 80% light transmission in the visible range (380-750nm), color neutrality. The surfaces offered prolonged effectiveness with use-test cases, maintaining their antimicrobial activity even after a rigorous wipe testing procedure.

“This is a great example of creating a multi attribute product while co-optimizing the attributes high efficacy antimicrobial properties that work under dry test conditions for touch enabled, display use test cases. Our goal was to show the connections with biological performance and physical attributes, and provide further guidance for future research,” said Wageesha Senaratne, researcher at Corning and leading co-author of the study.

“This new approach of considering the dewetting process opens to a variety of new possibilities to exploit some specific properties of metals while being able to thoughtfully change the others,” said Alessia Mezzadrelli, author of the study and Ph.D. student of the Nano-Glass project.

“Here for example, we were able to preserve the powerful antimicrobial effect of the copper while obtaining transparency and insulation despite the use of a metal.”

This research has been partially funded by the Nano-Glass project, a Marie Sklodowska-Curie Innovative Training Network, which is aimed at developing innovative nano-structuring designs and methods for advanced glass screens for a better display of information as well as new optical fibers for information security.

“While further development is necessary for full-fledged commercial deployment, this is a step in the right direction to enable antimicrobial touch screens for public or personal displays,” said Prantik Mazumder, researcher at Corning and co-author of the study.

“The proof-of-concept surface we have developed with Corning is an example of our continuous joint efforts in the development of enhanced multifunctional display screen glass using nano-structuring,” said Valerio Pruneri, ICREA professor at ICFO and coordinator of the Nano-Glass project.

Other researchers included ICFO researcher Christina Graham and colleagues from Corning Santona Pal, Dean Thelen and Lisa Hepburn.

Tagged categories: Antimicrobial coatings; Coating chemistry; Coating Materials - Commercial; Coatings; Coatings Technology; Coatings technology; Coatings Technology; Copper; Glass; Glass coatings; Health & Safety; Health and safety; Program/Project Management; Research and development