WEDNESDAY, MARCH 27, 2024

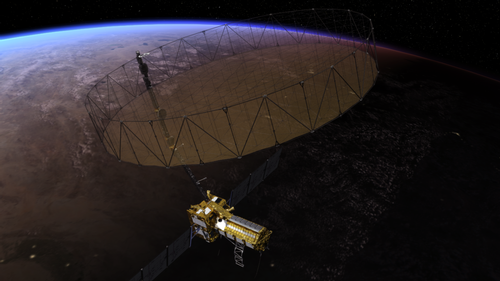

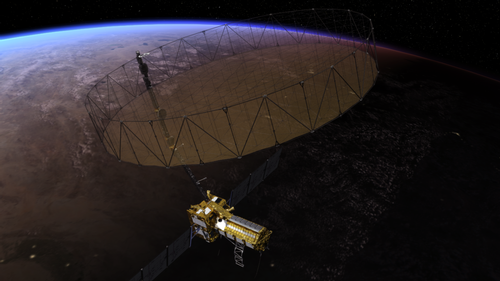

The United States National Aeronautics and Space Administration and Indian Space Research Organization's joint ASA ISRO Synthetic Aperture Radar (NISAR) satellite is nearly complete and will be ready to launch after coating work is completed.

The new satellite is reportedly part of the administration’s earth-observing mission, as it will monitor any change in almost all of planet’s land and ice surfaces.

About the Mission

According to NASA, the launch readiness date will be announced at the end of April, after which the spacecraft will launch from the Satish Dhawan Space Centre on India’s southeastern coast.

Work that still needs to be finished before launch reportedly includes applying a special coating to hardware components on the satellite’s 39-foot-diameter radar antenna reflector, one of NASA’s primary contributions to the mission.

Additionally, the application of the special coating will be a precautionary step to reduce any temperature increases that may affect the deployment of the reflector. Researchers stated that it can limit the temperature by reflecting solar radiation off the reflector hardware.

|

| NASA |

|

The United States National Aeronautics and Space Administration and Indian Space Research Organization's joint ASA ISRO Synthetic Aperture Radar (NISAR) satellite is nearly complete and will be ready to launch after coating work is completed. |

Testing and analysis studies had reportedly found a potential for the reflector to experience temperatures that were higher than expected in its stowed configuration in flight.

For science operations, researchers plan to use the reflector to transmit and receive microwave signals on Earth’s surface, potentially allowing NISAR to scan most of the planet’s land and ice surfaces twice every 12 days to collect data.

Due to the reflector’s size and complexity, it is being shipped from the ISRO site in India where the satellite is being assembled, then it will go to a specialized facility in California for the thermal coating to be applied and verified.

Additionally, as the reflector returns to India, teams from NASA’s Jet Propulsion Laboratory and ISRO plan to apply the coating to the satellite.

NISAR is reportedly the first hardware collaboration between NASA and ISRO on an Earth-observing mission. NASA states that it is a very new and powerful satellite which combines two kinds of synthetic aperture radars.

The project will reportedly provide measurements of Earth’s evolving surface, including changes in ice sheets and glaciers, wetlands and forests, and land around volcanoes and earthquake faults.

According to the ISRO, the mission will be conducted in three phases, which include:

Other NASA Coatings Projects

In November of last year, NASA announced that its X-59 quiet supersonic aircraft would be getting a new paint scheme to help protect it from moisture and corrosion.

According to NASA’s release, the new scheme was applied at the paint barn at Lockheed Martin Skunk Works’ facility in Palmdale, California.

The aircraft’s new design reportedly included a mainly white body, with a NASA “sonic blue” underside and red accents on the wings. Additionally, the X-59’s new design included safety markings to help with ground and flight operations.

NASA stated that its aircraft was moved to the paint barn on Nov. 14. Once it was painted, the team reportedly planned to take final measurements of its weight and exact shape to improve its computer modeling.

NASA added that the X-59 is an experimental aircraft built to fly faster than the speed of sound, subsequently reducing the sound of the typical sonic boom to a gentle thump. It is reportedly the centerpiece of NASA’s Quesst mission.

Through Quesst, NASA planned to fly the X-59 over several U.S. communities and gather data about people’s perceptions about the sound it makes. NASA stated that it would then give that data to regulators to potentially adjust current rules that prohibit commercial supersonic flight over land.

At the beginning of October 2023, NASA announced that it would be pushing the date for the first flight in its Quesst mission to 2024.

It stated that the reason behind the delay was that engineering teams involved with the mission needed more time "to fully integrate systems into the aircraft and ensure they work together as expected."

Additionally, NASA said the team was resolving intermittent issues with some of the “safety-redundant” computers on the plane.

Also, earlier this month, crews at NASA painted a new “worm” logo on the Space Launch System (SLS) solid rocket boosters and Orion spacecraft’s crew module adapter for the upcoming Artemis II mission in 2025.

NASA explained that the logo was created in 1975 by the firm of Danne & Blackburn as a modern emblem for the agency and returned after nearly 30 years in 2020 for limited use on select missions and products.

NASA’s Exploration Ground Systems and prime contractor Jacobs reportedly started painting the red logotype onto the parts that form the Moon rocket’s two solid rocket boosters Jan. 22, at the Kennedy Space Center in Florida.

To do so, NASA stated that crews used a laser projector to mark off the location of the logo with tape, then applied two coats of paint and added several coats of clear primer.

According to the release, each letter of the worm logo is around 6 feet and 10 inches in height, and the logo stretches 25 feet from end to end, or a little less than the length of one of the rocket’s booster motor segments.

The worm logo was reportedly placed in a different spot than where it was on Artemis I. While it will still be located on each of the rocket’s 17 story boosters, the logo is now placed toward the front of the booster systems tunnel cover.

NASA added that the SLS boosters are currently the largest, most powerful solid propellant boosters ever flown and give over 75% of the thrust at launch.

Workers reportedly applied the worm logo and European Space Agency insignia on Jan. 28 on the spacecraft’s crew module adapter at the Neil Armstrong Operations and Checkout Building at Kennedy.

The adapter reportedly holds electronic equipment for communications, power and control, and has an umbilical connector that bridges the electrical, data and fluid systems between the main modules.

Tagged categories: Aerospace; aircraft; Coating Application; Coatings; Coatings Technology; Environmental Controls; Environmental Protection; Government; NASA; Ongoing projects; Program/Project Management; Reflectance; Reflective coatings; Research; Research and development; Solar reflectance