THURSDAY, DECEMBER 14, 2023

A joint team at the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM has recently succeeded in testing coating drones to protect wind turbine rotor blades against ice.

According to a release from the organization, the TURBO project is under development by researchers from the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM, and the Fraunhofer Institute for Manufacturing Engineering and Automation IPA.

Icy Rotor Blades

According to the release, damp and cold conditions are not ideal for wind power structures. If a layer of ice builds on rotor blades, it can reportedly result in a rotational imbalance and increased wear. When this happens, the turbines may have to be shut down for several days, leading to losses for the operators from the pause in electricity production.

Fraunhofer states that traditional methods of protecting wind turbines from ice damage, like heating mats integrated in the blades or systems to pump warm air into the rotors, can be very expensive. Additionally, the same problem exists for the use of helicopters to spray de-icing agent onto the turbines.

|

| Photos: Fraunhofer IFAM |

|

A joint team at the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM has recently succeeded in testing coating drones to protect wind turbine rotor blades against ice. |

“Drones that are only used when needed offer a cost-effective alternative,” said Andreas Stake, project manager at Fraunhofer IFAM.

According to the researchers, in order to use drones to prevent ice, a number of conditions have to be met. On top of being environmentally friendly, the coating materials reportedly need to show good adhesion and durability to remain on the rotors for weeks and protect them from ice.

Additionally, the spraying system used has to be very accurate and lightweight. Finally, the drones need to have a high payload and allow for very precise control.

Project Research

Researchers working on the project stated that they had succeeded in building a prototype to meet all of these needs. The coating material designed by the scientists at Fraunhofer IFAM in Bremen, Germany, is reportedly constructed out of urea and wax, is environmentally friendly and has sufficient adhesion.

According to the team, the material can be applied quickly with a spray technique and also has a fast dry time. The coating reportedly went through testing in an ice chamber at the institute to confirm that it can consistently protect against frost.

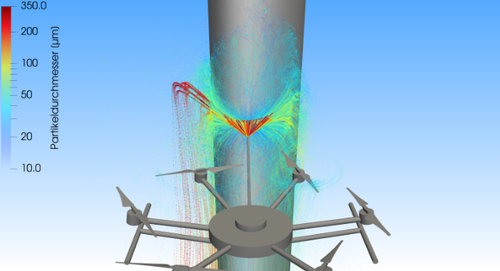

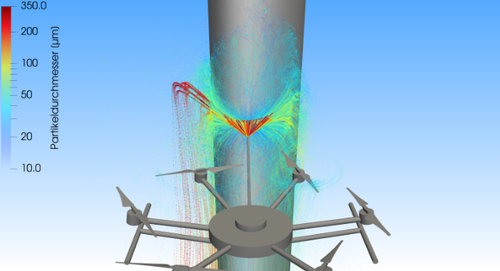

The team at Fraunhofer IPA reportedly constructed the equipment to apply the coating, which consists of a small pump that releases the fluid urea/wax mixture at high pressure into a long, thin lance, at the tip of which is a nozzle with a diameter of just 0.3 millimeters.

The airless pump system is reportedly capable of producing droplets with a diameter of 100 micrometers. Even at wind speeds of around 21 miles per hour, the droplets can still be sprayed accurately onto the edges of the rotor blades where they solidify.

The edges, according to the release, are specifically important to this process since it is where the icing process starts when wet, cold air hits the turbine.

|

|

According to the team, the material can be applied quickly with a spray technique and also has a fast dry time. The coating reportedly went through testing in an ice chamber at the institute to confirm that it can consistently protect against frost. |

Dr. Oliver Tiedje, project manager at Fraunhofer IPA, and his team reportedly found the technical parameters such as the required pressure, an efficient atomization method and the optimum droplet size, using fluid dynamic simulations.

“Our decades of experience in modeling coating processes really helped us out. We were able to draw on this expertise,” said Tiedje. “However, we did have to adapt the process parameters to the complex geometry of the wind turbines.”

Now, researchers state that they intend to work with industry partners in developing the technique and getting it ready for series production. There are reportedly several applications for drones to be used to apply coatings, ranging from ice protection for wind turbines to overhead lines in rail transport to building refurbishment.

The release states that as an example, the drones could work to repair defects in render on parts of buildings that are difficult to reach.

The "TURBO: Temporary coating by means of drones—Icing protection of wind turbines as a case study" project was reportedly backed by 19 companies, including coating and raw material manufacturers, manufacturers of coating equipment and drones and operators of wind turbines.

The project was submitted to the German Federation of Industrial Research Associations through the Research Society for Pigments and Paints as an Industrial Collective Research project and is being funded by the Federal Ministry for Economic Affairs and Climate Action.

Similar News

At the beginning of the year, technical service provider TÜV Nord recently announced that it was using drone support for an end-of-warranty inspection for a European wind turbine manufacturer. The pilot project was photographing concrete tower parts of concrete-steel hybrid wind turbines to find abnormalities and evaluate the structures.

According to the company, concrete tower parts of concrete-steel hybrid towers on wind turbine can show abnormalities in the material a few years after construction.

For the pilot project, the entire concrete tower was photographed by drone, with TÜV Nord experts using those images to evaluate the structure. In the interim, an automated image recognition system was also used to pre-sort images with “conspicuous features” on the basis of extensive training data so that the experts could view and evaluate the images in an even more targeted manner.

TÜV Nord reported that 34 of the manufacturers wind turbines were assessed in 2022 using the drone-based inspection. Those results were reportedly also validated.

It explained that the procedure would be extended to additional sites. According to TÜV Nord, talks were underway with other manufacturers and wind farm operators.

Also, in March, AI-assisted digital inspection software provider Qii.AI announced that it had entered into an agreement with Canada’s Naval Engineering Test Establishment for use of the platform in the Royal Canadian Navy’s ship inspection program.

Using the system, the company reported that ship inspections from drone imagery could be completed in a fraction of the time taken for traditional methods. The process was accelerated even further by artificial intelligence, automating the detection and measurement of issues in need of remediation, such as corrosion.

The technology offers the potential to be applied broadly across military and non-military shipping assets, additionally this was reportedly the first of many such engagements with the Canadian Armed Forces as well as NATO partner forces.

The visual data gathered for the new ship-inspection program was reportedly expected to be carried out using small inspection drones from Skydio.

Tagged categories: Coating Application; Coating Materials; Coatings; Coatings Technology; drone; Drones; icephobic; Program/Project Management; Quality control; Research; Research and development; Spray equipment; Technology; Tools; Weathering; Wind Towers