THURSDAY, JULY 27, 2023

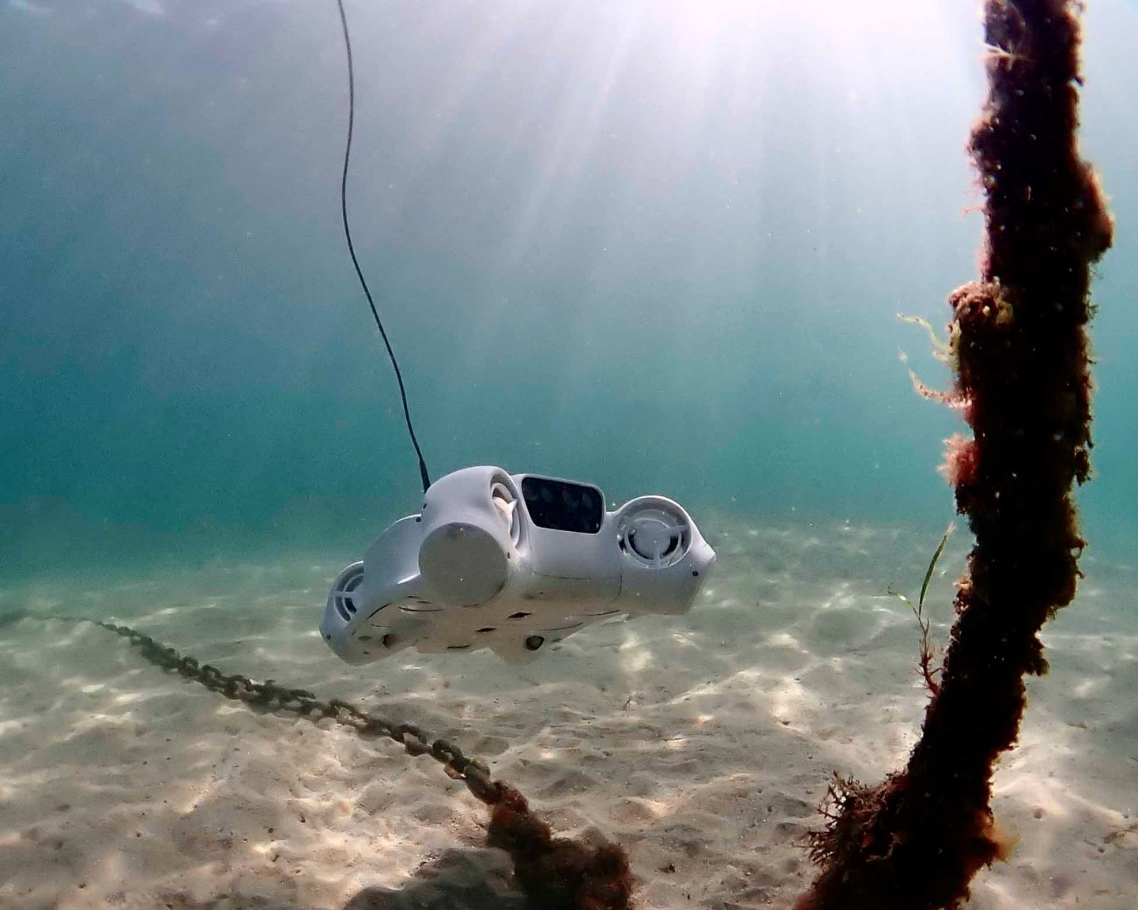

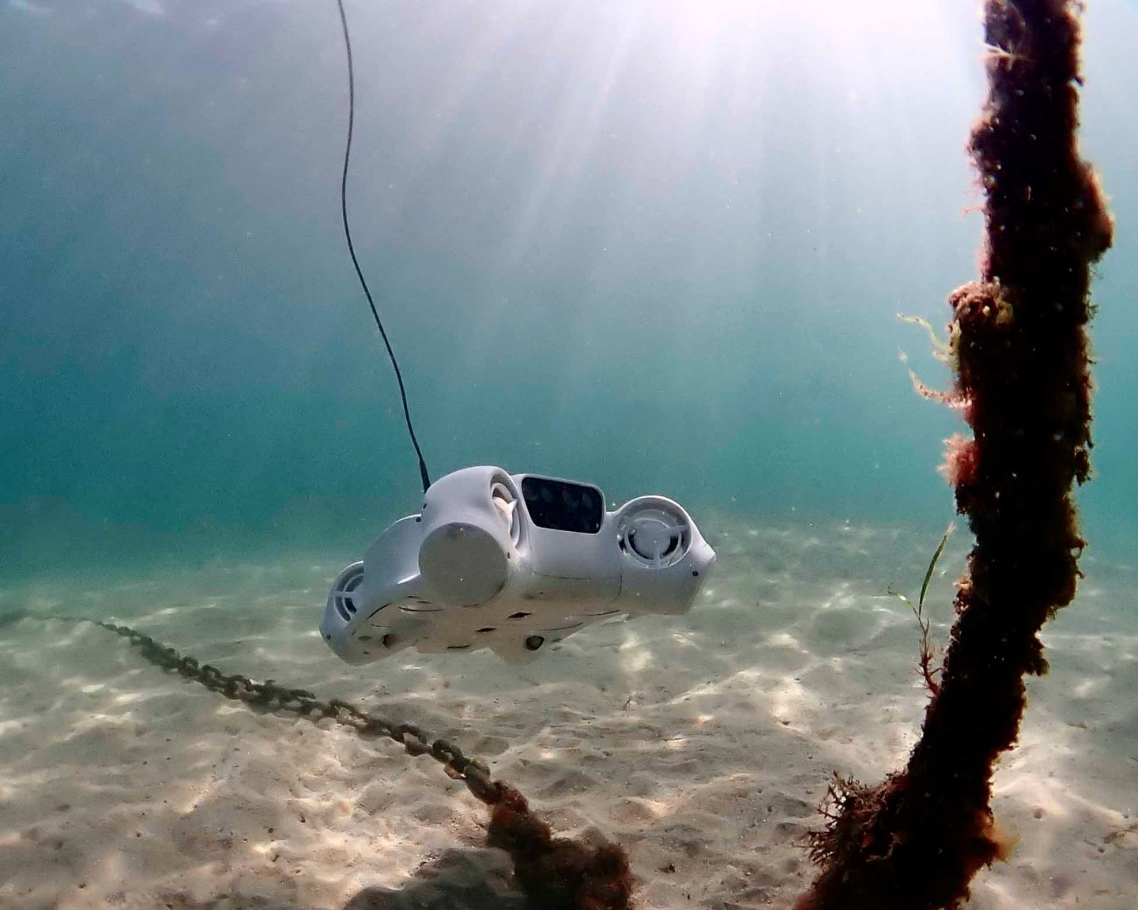

A Sydney, Australia-based startup has reportedly developed an autonomous underwater robot that can inspect and clean biofouling on ship hull surfaces.

The Hullbot is “an underwater drone which inspects, maps and interacts with [and cleans] submerged structures,” Tom Loefler, CEO and Co-Founder of Hullbot, told Cosmos.

According to the company, Hullbot enables gentle cleaning with soft brushes early on in the process, to proactively remove early-stage slime before macrofouling begins without damaging the antifouling paint beneath.

|

| Hullbot |

|

A Sydney, Australia-based startup has reportedly developed an autonomous underwater robot that can inspect and clean biofouling on ship hull surfaces. |

About Hullbot

According to reports, biofouling can include slime, barnacles, weeds, and algae that can grow on ship hulls in just a short amount of time. The slime then forms the base for multicellular life to build up on the hull in the form of macrofouling, which Loefler says that can slow boats and require more energy and fuel consumption to keep them moving.

“The [vessels] have a slime layer over their surface within several days that can dramatically increase the energy required to push them through the water. And that of course, increases their fuel costs,” he said.

The International Energy Agency reports that in 2022, international shipping accounted for about 2% of global energy-related CO2 emissions. In an effort to reduce this number, the International Maritime Organization (IMO) recently adopted a new strategy on reducing greenhouse gas emissions from ships, which includes an “enhanced common ambition” to net zero greenhouse gas emissions from international shipping close to 2050.

While shipowners can reportedly slow the macrofouling process by applying antifouling coatings to the underside of a ship, many of these biocide-containing coating formulations release toxins and microplastics into the ocean, while the surface preparation and need for frequent coating reapplication can make these methods unfeasible.

According to the company, Hullbot’s ability to perform frequent, light-duty cleaning can lower the cost of each clean so that it can be done more often.

“The more often you clean, the less fuel consumption the vessel will have. So ideally, we clean fortnightly or more frequently than that, to avoid hard growth, and we clean weekly or more often to keep fuel costs as low as possible,” says Loefler.

According to Loefler, Hullbot developed a proprietary underwater vision system that uses cameras and code, in combination with a number of other sensors, to enable their robot to efficiently navigate underwater, compared to the limitations of traditional GPS-, WiFi- and 5G-based autonomous systems.

“There are many challenges underwater that are unique, such as the distortion of light, the turbidity of the water column… bubbles and other effects. Everything around the robot is moving: the water is moving, the light is moving, the bubbles are moving, and the boat is moving,” said Loefler.

“A number of different cameras interpret the environment around the robot, and plan how it can move through 3D space to inspect or map or interact.”

The robot reportedly operates with a tether for power and data and is able to swim freely through the water using its thrusters, cleaning the hull with soft, rotating brushes with both the speed and pressure applied controlled without the need for a human operator.

Next Steps

Hullbot’s technology is reportedly being trialed across a number of other applications through partnerships with marine industries, marinas, research institutes and environmental organizations in Australia.

In the future, Loefler says that he believes that cleaning daily with Hullbot could eliminate the need for antifouling coatings entirely.

“We would like to offer a solution where hulls are coated with a durable, nontoxic anti foul and cleaned weekly by robots. And in the future, we can see no antifouling coating at all. Just say, a hard gel coat or a hard epoxy coat and cleaning every day with a robot.”

More information about the Hullbot technology can be found here.

Tagged categories: Antifoulants; Environmental Controls; Health & Safety; Marine; Metal cleaning; PaintSquare; Program/Project Management; Quality Control; Robotics; Ships and vessels; Surface preparation; Surface Preparation; Technology; Tools & Equipment