MONDAY, JUNE 12, 2023

A team of researchers at Drexel University and the State University of New York are examining how artificial intelligence, alongside mathematical methods, can determine how damaged a concrete structure is.

The paper, “A graph-based method for quantifying crack patterns in reinforced concrete shear walls,” was recently published in the journal Computer-Aided Civil and Infrastructure Engineering and led by Arvin Ebrahimkhanlou, Ph.D., an assistant professor in Drexel’s College of Engineering, and doctoral student Pedram Bazrafshan.

About the Process

Currently, inspectors visually examine concrete structures for cracking, chipping or water penetration, taking measurements of the cracks and noting whether or not they have changed in the time between inspections. If enough of these conditions are present and appear to be in an advanced state, according to a set of guidelines on a damage index, then the structure could be rated “unsafe.”

“Without an autonomous and objective process for assessing damage to the many reinforced concrete structures that make up our built environment, these tragic structural failures are sure to continue,” Ebrahimkhanlou said.

“Our aging infrastructures are being used beyond their design lifespan, and because manual inspections are time-consuming and subjective, indications of structural damage may be missed or underestimated.”

Additionally, Drexel notes, this process takes time and could leave too much room for subjectivity.

|

| Photos: Drexel University |

|

A team of researchers at Drexel University and the State University of New York are examining how artificial intelligence, alongside mathematical methods, can determine how damaged a concrete structure is. |

“The same crack in a reinforced concrete structure can appear menacing or mundane—depending on who is looking at it,” Bazrafshan said. “A crack can be an innocuous part of a building’s settling process or a telltale sign of structural damage; unfortunately, there is little agreement on precisely when one has progressed from the former to the latter.”

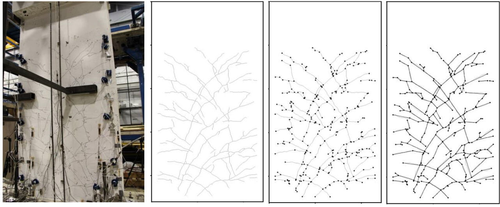

In an effort to find a solution, the team created a method to precisely quantify the extent of cracking by employing a mathematical method called graph theory. This process reportedly pinpoints its graph features, such as the number of times cracks intersect on average.

According to the release, Ebrahimkhanlou originally developed the process for using graph features to create a kind of “fingerprint” for each set of cracks in a reinforced concrete structure. By comparing the prints of newly inspected structures to those of structures with known safety ratings, it can produce a quick and accurate damage assessment.

“Creating a mathematical representation of cracking patterns is a novel idea and the key contribution of our recent paper,” Ebrahimkhanlou said. “We find this to be a highly effective way to quantify changes in the patterns of cracking, which enables us to connect the visual appearance of a crack to the level of structural damage in a way that is quantifiable and can be consistently repeated regardless of who is doing the inspection.”

The team then used AI pixel-tracking algorithms to convert images of cracks to their corresponding mathematical representation in a graph. They also had a machine learning program to extract graph features from a set of images of reinforced concrete shear wall structures with different height-to-length ratios.

“The crack-to-graph conversion and feature-extraction processes take just a minute or so per image, which is a significant improvement by comparison to the inspection process which could take hours or days to make all of the required measurements,” Bazrafshan said. “This is also a promising development for the possibility of automating the entire analysis process in the future.”

|

|

Drexel reports that the researchers trained a second algorithm to correlate the extracted graph features with a tangible scale showing the amount of damage imposed on the structure, focusing on images that showed moderate cracking. |

Drexel reports that the researchers trained a second algorithm to correlate the extracted graph features with a tangible scale showing the amount of damage imposed on the structure, focusing on images that showed moderate cracking.

The program reportedly assigned a weighted value to each of these features, depending on how closely they correlated with mechanical indicators of damage, to produce a quantitative profile against which the algorithm could measure new samples to determine the extent of their structural damage.

The team then used images of three large-scale walls that had been mechanically tested in a lab at the University at Buffalo to determine their conditions to test the algorithm. The researchers reported that, in each case, the program was able to correctly assess the damage with greater than 90% accuracy.

“This is just the first step in creating a very powerful assessment tool that leverages volumes of research and human knowledge to make faster and more accurate assessments of structures in the built environment,” Ebrahimkhanlou said.

“Imposing order on a seemingly chaotic set of features is the essence of scientific discovery. We believe this innovation could go a long way toward identifying problems before they happen and making our infrastructures safer.”

Now, the group reportedly plans to continue its work by training and testing the program against larger and more diverse datasets, including other types of structures. They are also working toward automating the process so that it could be integrated into structural monitoring systems, as well as the process of collecting photos and video of damaged structures following earthquakes and other natural disasters.

The experimental data used was reportedly supported by the National Science Foundation.

Tagged categories: Colleges and Universities; concrete; Concrete defects; Cracking; Good Technical Practice; Health & Safety; Health and safety; Program/Project Management; Research; Research and development; Safety; Technology