TUESDAY, JANUARY 17, 2023

Last week, industrial machinery manufacturer Kawasaki Heavy Industries, Ltd. announced the successful completion of its joint offshore verification test for close-range inspections using an autonomous underwater vehicle (AUV).

Conducted off of Awaji Island in Hyogo Prefecture, Japan, the AUV measured the electrical potential of subsea pipelines for French energy supermajor TotalEnergies.

About SPICE

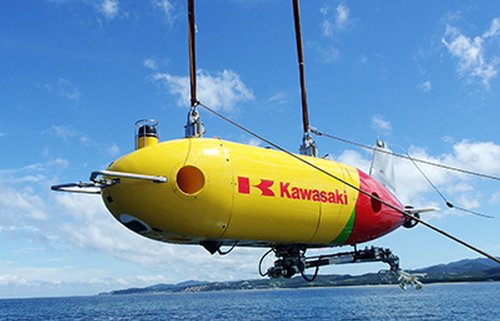

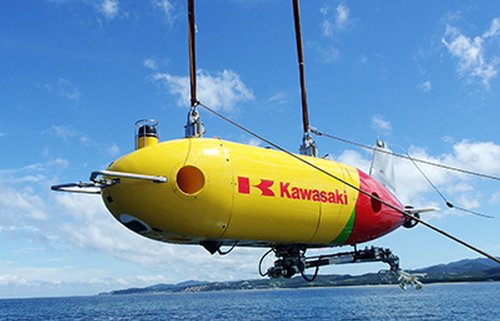

According to Kawasaki, the AUV is the world’s first with a robot arm for subsea pipeline inspections. The design deciion was notably made in response to the growing demand for subsea pipeline maintenance in offshore oil and gas fields. The vehicle is named SPICE, or Subsea Precise Inspector with Close Eyes.

Overall, SPICE has a length of approximately 5.6 meters (about 18.3 feet), a width of 1.4 meters and a height of 1.1. meters. In the air, it weighs approximately 2,500 kilograms (about 2.75 tons). It can also reach a maximum depth of 3,000 meters at a max speed of 4 knots.

SPICE features a main propulsion propeller, two side thrusters and two vertical thrusters. It uses an inertial navigation system and sonar for its navigation equipment, as well as ballast release equipment and an iridium beacon for safety.

|

| Kawasaki Heavy Industries, Ltd. |

|

Last week, industrial machinery manufacturer Kawasaki Heavy Industries, Ltd. announced the successful completion of its joint offshore verification test for close-range inspections using an autonomous underwater vehicle (AUV). |

A 2020 verification test reportedly achieved stable pipe-tracking performance, demonstrating high capability as a platform for close-range subsea pipeline inspections. This was conducted the “Joint Technological Development Support Program for Offshore Oil and Natural Gas Fields” of DeepStar and The Nippon Foundation Ocean Innovation Consortium.

Afterwards, Kawasaki launched a joint research project proposed by TotalEnergies to integrate the energy company’s electrical potential measurement technology Light Touch Cathodic Protection (LTCP) with SPICE. This was anticipated to make the AUV capable of measuring the electrical potential gradient of a pipeline allowing the detection of potential coating defects.

The basic design was reportedly completed between October 2020 and February 2021, with various integration simulations performed. In August 2021, a more detailed design and modifications of SPICE were conducted to incorporate TotalEnergies’ LTCP.

Latest Trial

The most recent verification test off Awaji Island ran from Aug. 30, 2022 to Sept. 2, 2022, reportedly resulting in the successful measurement by LTCP integrated with SPICE of the electrical potential of subsea pipelines. For the offshore test, simulated pipes and a corrosion protection system were placed on the seabed under the supervision of TotalEnergies.

SPICE, utilizing the time-tested, pipe-tracking capability and precise autonomous control of the robot arm, then successfully performed measurements of electrical potential using the robot arm with its newly integrated measurement device to check the pipelines’ state of protection against corrosion inferred by the measurement of the electrical potential.

“LTCP had demonstrated its repeatability of establishing the effectiveness of the cathodic protection system in a controlled test environment, and there was a need to deploy the technology in close proximity to the pipe under inspection. SPICE with the ability to deploy sensors at a controlled distance, enabled LTCP to demonstrate repeatable performance,” commented Andy Gower, R&D Subsea Robotics Project Leader of Stavanger Research Centre at TotalEnergies.

“The potential for additional sensors to be deployed at the same time, should enable other non-destructive test sensors and techniques, providing enhanced data of aging pipeline and allowing integrity threats to be assessed with more detail. The future trend of subsea robotics is for highly maneuverable sensor platforms, and the performance of LTCP integrated with SPICE, provides an effective solution to determine the performance of the cathodic protection system in an operational context.”

Kawasaki reports that the successful outcome suggests that SPICE can achieve automation and reduce operational time in close-range subsea pipeline inspections currently performed by Remotely Operated Vehicles (ROVs), including measurement of electrical potential.

“We have combined self-own technologies of underwater vehicle and industrial robot to develop an AUV with an arm called SPICE. By using the arm, we are confident in accurately positioning the sensor to the target where proximity is required,” said Noriyuki Okaya, Manager of Development & Design Section, AUV Department, Ship & Offshore Structure Business Division at Kawasaki.

“We are very pleased to receive the great opportunity of this joint offshore verification sea trial from TotalEnergies. In this sea trial, we could obtain useful inspection data in combination with LTCP and also could demonstrate the ability of SPICE as a pipeline proximity inspection platform, continuing from 2020. We will continue to develop it in search of further possibilities.”

Other Underwater Pipeline Technology

In January 2021, Norwegian technology company Eelume Subsea Intervention developed a six-meter-long, snake-like robot to serve the deep-sea oil and gas industry. The autonomous disruptive technology, referred to at Eelume, is designed to perform maintenance, inspections and repair on underwater infrastructure to make work safer, cheaper and less polluting.

According to Eelume Subsea Intervention, Eelume was designed after a decade of research on snake robots in collaboration with independent research organization SINTEF. However, the technology originally established itself in 2015 as a spin-off from the Norwegian University of Science and Technology.

The company reports that the underwater technology is basically a self-propelled robotic arm designed to live permanently under water, where they can be mobilized around the clock, regardless of ocean currents. Having constant access to continuous inspection, maintenance and repair capabilities near the subsea installations without the need for surface vessels means greener, safer and less costly subsea operations, ESI says.

Looking at more specific numbers, Eelume can be kept at docking stations up to 500 meters (547 yards) deep for up to six months without being brought back to the surface and can travel up to 20 kilometers (12.4 miles) before needing to recharge.

In addition to performing maintenance on underwater infrastructure such as wells, pipelines and other equipment, Eelume can also swap out parts for different tasks, including tools to operate subsea valves, and cleaning brushes to remove marine growth and sediments. Thanks to its snake-like design, the underwater robot can work in confined spaces and wriggle its body to stay in place during unfavorable weather conditions.

During these tasks—which can be assigned from onshore— Eelume will also send back video and data.

Tagged categories: Coatings; Corrosion protection; Inspection; Inspection equipment; Offshore; Paint defects; Pipelines; Pipes; Program/Project Management; Research and development; Robotics; Technology; Testing + Evaluation