THURSDAY, AUGUST 18, 2022

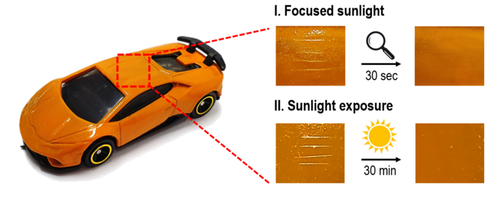

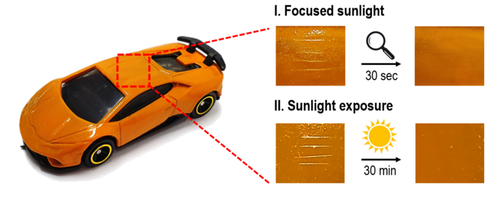

Researchers from the Korea Research Institute of Chemical Technology have reportedly developed a transparent automotive coating material that can self-heal in 30 minutes when exposed to sunlight.

The study, recently published in the journal ACS Applied Polymer Materials, was authored by a research team of Dr. Jin Chul Kim, Dr. Young il Park and Dr. Ji-Eun Jeong. The study was supported by the Ministry of Science and ICT (Korea) and was conducted through the New Career Researcher Program of the National Research Foundation of Korea and KRICT.

About the Research

According to the news release, durability of automotive coatings is the most important issue in protecting a vehicle surface, while the protective coating should be colorless and transparent to see the original color underneath.

However, providing self-healing qualities while maintaining these conditions can be difficult to achieve. Materials with free molecular movement have high self-healing efficiency, but have low durability, whereas materials with high hardness and excellent durability have remarkably poor self-healing performance.

To resolve this, the KRICT research team looked to utilizing sunlight to raise the surface temperature and convert the light energy to thermal energy. The increased surface temperature then can reportedly self-heal a surface scratch by repeating the dissociation and recombination of chemical bonds in the polymer structure.

|

| Korea Research Institute of Chemical Technology |

|

Researchers from the Korea Research Institute of Chemical Technology have reportedly developed a transparent automotive coating material that can self-heal in 30 minutes when exposed to sunlight. |

The researchers coated a laboratory-scale model car using a spray coating machine with the developed material, then exposed it to midday sunlight. After about 30 minutes, the scratch had completely disappeared, and the coating material was restored.

The coating reported has a similar performance to commercial protective coatings. To the existing commercial coating resin, the research team adds a dynamic chemical bond (hindered urea structure) that can repeat the decomposition and recombination of the polymer structure.

This then can be mixed with a transparent photothermal dye so that dynamic chemical bonding can occur actively upon exposure to sunlight, particularly near infrared sunlight in the wavelength range of 1,000 to 1,100 nm.

Previously, photothermal dyes have been studied for self-healing functions, but they were mainly based on inorganic materials that are difficult to apply industrially since they are not transparent. Inorganic materials also require a large amount of light energy to produce a photothermal effect.

Using a transparent organic photothermal dyes that can absorb near-infrared light, which accounts for less than 10% of midday sunlight, the researchers discovered it can circumvent excessive increase of the vehicle surface temperature. Additionally, organic photothermal dyes do not affect the product color due to colorless inherent color, easily blend with various paints and are inexpensive.

The KRICT team notes that the self-healing material can be used as a coating for transportation applications, electronic devices such as smartphones and computers, and building materials in the future. It can also reportedly aid carbon neutrality, reducing the use of harmful organic solvents used when repainting vehicles.

“The developed technology is a platform technology that synthesizes self-healing coating materials using both inexpensive commercial polymer materials and photothermal dyes. It is expected to be widely used not only in automotive clearcoats but also in various applications,” said Dr. Jin Chul Kim from KRICT, the research director.

Recent Self-Healing Coating Research

Last year, in November, researchers at Rice University in Houston developed an anticorrosive and self-healing coating for steel. The experiment, published in Advanced Materials, was joint researched between Rice and the South Dakota School of Mines and Technology.

The development stems from research conducted by Pulickel Ajayan, a scientist at the Rice lab of materials, who originally created a compound composed of sulfur and selenium, which was shown to be more insulating than most flexible materials and more flexible than most dielectrics.

The lightweight sulfur-selenium alloy “combines the best properties of inorganic coatings like zinc- and chromium-based compounds that bar moisture and chlorine ions but not sulfate-reducing biofilms, and polymer-based coatings that protect steel under abiotic conditions but are susceptible to microbe-induced corrosion.”

Scientists placed small slabs of mild steel treated with the coating alongside plain steel in seawater for a month. According to Rice, the coated steel showed no discoloration or other change, but the bare steel rusted significantly.

The lab also exposed these samples to plankton and biofilms for 30 days, simulating sulfate-reducing bacteria that accelerate corrosion. The inhibition efficiency for the coating was calculated as 99.99%.

According to the release, the compound performed well compared to commercial coatings with a similar thickness of about 100 microns.

“Atop all that, we found the viscoelastic coating is self-healing,” said Rice graduate student and co-lead author M.A.S.R. Saadi.

“If you give the alloy a poke, it recovers,” said materials scientist Muhammad Rahman, principal investigator on the study and an assistant research professor of materials science and nanoengineering in the George R. Brown School of Engineering. “If it needs to recover quickly, we assist it using heat. But over time, most thick samples will recover on their own.”

To test the self-healing properties, the researchers cut a film in half and place them on a hotplate. The pieces reportedly reconnected in about two minutes when heated to about 70 C (158 F) and could be folded just like the original film. Pinhole defects were healed by heating them at 130 C (266 F) for 15 minutes.

Tagged categories: Automotive coatings; Coating chemistry; Coating Materials; Coatings; Coatings Technology; Colleges and Universities; Organic Coatings; Program/Project Management; Research and development; Self-healing