MONDAY, FEBRUARY 14, 2022

With a goal of replacing harmful hexavalent chrome coatings, Trion Coatings LLC (South Bend, Indiana) has developed a new safe and environmentally friendly chrome coating. SAFE Chrome is a non-aqueous, trivalent chromium chemistry that can reportedly match the performance of traditional hex coatings.

While hex chrome provides hardness, wear resistance, corrosion resistance and enhanced adherence, it has also been proven to be carcinogenic and can pose occupational and environmental hazards.

While several regulations have been implemented over the years—including the Occupational Safety and Health Administration lowering the Permissible Exposure Limit for hexavalent chromium in 2006, the National Institute for Occupational Safety and Health publishing a new Recommended Exposure Limit in 2013 and The American Conference of Governmental Industrial Hygienists publishing a new Threshold Limit Value in 2018—Trion set out to find a new chrome plating technology to create a safer work environment.

“This technology will fundamentally change the surface finishing industry by allowing chrome-plated steel to be produced in a way that is energy efficient, environmentally friendly and safe for workers,” said Doug Morrison, President and Co-founder of Trion Coatings, when SAFE chrome was announced. “The industry has worked carefully and responsibly over the years with hexavalent chrome, but the core carcinogenic characteristics of this process has been a concern for chrome platers and safety regulators for decades.

“Trion’s Trivalent (Cr3) process is a welcome game changer that aligns with the safety vision of regulatory agencies across the globe, while also maintaining the strength and performance of the coating for its products.”

|

| Trion Coatings LLC |

|

With a goal of replacing harmful hexavalent chrome coatings, Trion Coatings LLC (South Bend, Indiana) has developed a new safe and environmentally friendly chrome coating. |

Development Background

In 2018, Trion announced that it had developed a new and environmentally friendly trivalent chrome plating technology. The company was formed at Notre Dame’s IDEA Center to develop an environmentally friendly alternative to hexavalent chromium for surface finishing applications.

According to Trion, Dr. Mauricio Quiroz-Guzman, Co-Founder and former postdoctoral researcher at Notre Dame and now chief scientist at Trion Coatings and Professor Patrick Benaben, a noted international electrochemistry expert served as the core technical team for developing the technology for commercial viability.

The patent-pending technology, which was branded as SAFE Chrome, uses trivalent chromium and a proprietary ionic liquid solution that reportedly offers aster electroplating speeds, improved wear resistance and higher performance results than traditional hexavalent chrome, in addition to its health and safety benefits.

A partnership with KCH Services, Inc. in 2019 helped deploy SAFE Chrome to customers and their operations, acting as Trion’s Engineering, Procurement and Construction (EPC) provider. Later that year, Trion also announced a partnership with Imagineering Finishing Technologies, LLC, to act as a Go-To-Market partner to deploy SAFE Chrome across markets globally.

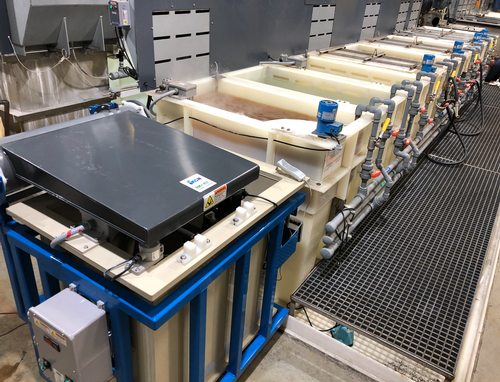

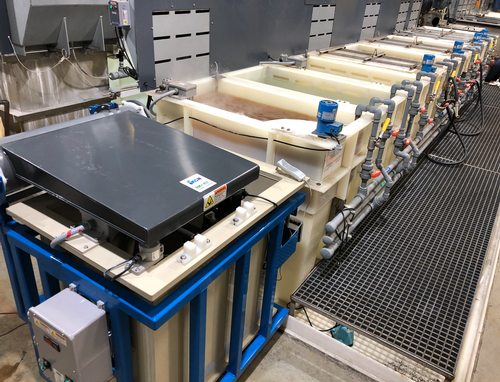

As part of that partnership, Trion installed a commercial scale plating line at Imagineering’s Center for Metal Finishing Excellence in South Bend, Indiana. Other partners have included Nucor Steel and Surface Technology Inc.

In September 2021, Trion announced a Cooperative Research and Development Agreement with the U.S. Army Combat Capabilities Development Command Armaments Center, headquartered at Picatinny Arsenal, New Jersey.

The agreement was expected to extend the company’s expertise in the electrodeposition of trivalent chrome, other metals and general use of ionic liquids in surface treatment of metallic substrates. Additionally, DEVCOM would help accelerate the development, prototyping and transitioning of the new technology to field applications.

SAFE Chrome Chemistry, Performance

Trion reports that SAFE Chrome meets standards for commercial specifications and functional applications, while also providing a safe environment for employees. It is Restriction of Hazardous Substances compliant and does not contain Cr6, PFOA or PFOS.

Trivalent solutions are typically water-based, requiring additives to assist in reducing trivalent chrome to chrome metal. However, SAFE Chrome uses an ionic liquid-based chemistry to achieve this.

The Cr3 ion is trapped inside of a highly stable bi-pyramidal complex, causing hydrogen evolution at the cathode and quickly changing the pH of the solution.

“You have all of these side reactions with all of these other components of that aqueous chemistry,” Morrison explained. “So it's not just water in the Cr3, it's water, Cr3 and five other ingredients to disrupt that bi-pyramidal complex.

“We’ve got basically three ingredients water, ionic liquid and chrome. We only have to manage these three ingredients and the ionic liquids disrupt that water Cr3 ion complex. Because of that, we’re able to produce Cr3at lower voltages, and we’ve got less hydrogen evolution and less pH evolution.”

SAFE Chrome can meet the specifications of required thin dense chrome (TDC), according to Trion, and exceeds the AMS 2438 wear resistance requirement. In Taber Abrasion Testing, the coating yielded sub 1.0 mass loss and also outperformed hex chrome in Falex Pin and VeeBlock testing.

Trion reports that its chrome coating can be used in a variety of industries:

In an effort to lower the costs of switching from hex chrome to SAFE chrome, Trion designed the solution to use similar equipment. The company also recommends considering lifecycle costs of a plating line, including the cost of electricity.

“From the beginning, we were committed to developing a technology that would be a drop-in replacement to the extent it could be,” Morrison said. “As a result, we now have a process that uses standard direct current rectification; uses no exotic materials; works without the use of hazardous lead anodes, works in open-air settings; and is an industrial compatible and robust technology. That’s been the mission from day one.

“You may have to replace the liner of a tank, you may need to adjust the rectification size. But you’re still using direct current rectification. We’re not using pulse plating or things of that nature. Depending on the application and State requirements, there’s likely no need to change an existing exhaust system or racking.”

Using the technology’s increased plating rate reportedly allows it to provide build thickness more quickly and lower costs, making it an investment over time in regard to efficiency.

“We have worked hard to develop and enhance our technology and we are now excited to be positioned to support the metal finishing industry transition away from hex chrome in a supportive way that will position those businesses for long-term safety and success,” Morrison said.

Tagged categories: Coating Materials; Coatings; Coatings technology; Coatings Technology; Corrosion resistance; Environmental Controls; Environmentally friendly; Health & Safety; Health and safety; Hexavalent chromium; Research; Research and development; Safety; Technology; Trion Coatings LLC