TUESDAY, JULY 27, 2021

Earlier this month, the Naval Surface Warfare Center, Port Hueneme Division (NSWC PHD) announced a new partnership with remote-sensing technology company Aerial Alchemy in an effort to solve how corrosion affects the performance of Navy ships’ combat systems and to find a way to detect corrosion remotely.

The partnership will reportedly operate under a Cooperative Research and Development Agreement (CRADA).

Tracking Corrosion

Getting the idea from unmanned aerial vehicles that use sensors to track and monitor wildlife, livestock, infrastructure, weather and construction progress, among other tasks, the NSWC PHD has now sought out scientists and California-based Aerial Alchemy to use these same systems to track corrosion and degradation on combat systems aboard Navy ships.

In partnering with Aerial Alchemy specifically, the NSCW PHD is slated to use its medium and heavy-lift UAVs, which use sensors equipped with lidar scanning and other imaging technology, to accurately capture data used to generate a 3D digital representation of a physical asset, also known as a digital twin.

The partnership’s overall goal is to explore using Aerial’s drones and its processing system and visual data to detect areas that may have corrosion. As a drone flies over a specified area of a ship, such as a hull or the rear, it transmits video to create a digital model of a ship that contributes to the ship's detailed analysis, including potential areas of concern for corrosion or rust.

|

| Latasha Ball, Department of Defense, Public Domain |

|

Earlier this month, the Naval Surface Warfare Center, Port Hueneme Division (NSWC PHD) announced a new partnership with remote-sensing technology company Aerial Alchemy in an effort to solve how corrosion affects the performance of Navy ships’ combat systems and to find a way to detect corrosion remotely.

|

According to Alan Jaeger, NSWC PHD Office of Research and Technology Applications manager, if the UAV and sensors are able to successfully detect corrosion, it will give scientists an early head’s up of the issue.

“The idea of the CRADA we are doing now is whether we can use various sensors to identify that information without having to put human eyeballs on it,” Jaeger said. “If we can, then the next step is putting that on drones or unmanned aircraft, so we don't have to send a sailor on a ship; we can send a drone, and it can scan equipment and identify corrosion or undersurface damage, for example. If we can get that data, then we can start pre-planning for maintenance, preventative maintenance and repair operations.”

The partnership is also anticipated to bring many benefits to the Navy and the warfighter, including reducing the labor costs of inspections and the ability to inspect difficult and high-risk areas.

“Because a lot of corrosion happens under the painted surface, you see it when it breaks through the painted surface, or you start to see physical flaws; and at that point, it's almost too late to do touch-up work, so the early detection will be very valuable for planning maintenance actions and for knowing which system needs the maintenance and which ones don't, as well as moving onto our condition-based maintenance model rather than our preventative based maintenance model,” said Zachary Stephens, NSWC PHD materials engineer.

In launching their combined research efforts, Aerial, alongside Jaeger, Stephens and Armen Kvryan, NSWC PHD lead materials engineer, plan to conduct first sensor tests in a laboratory in order to explore the different types of corrosion and degradation the sensors can identify on different kinds of metals, such as aluminum and steel.

“Our initial research will be on what sensors to use to detect corrosion and then figure out what sensors we can use and what materials we can detect corrosion or degradation on, because composites are not metal, so they don't corrode," Stephens said. "Although it would be ideal to have a (single) sensor that can detect all kinds of corrosion and degradation on the ship when you have composite versus aluminum or steel, they all have different signs and methods. One method may work on one type system but won't work on another; the success of this test will determine where to focus our efforts.”

Spaulding also agreed that if the technology successfully identified corrosion on combat systems, it could also assess issues on other parts of the ship and be useful to other industries.

“To make a commercially viable product outside the Navy, we must also investigate the material properties of the hull, superstructure and pretty much all exterior surfaces of the ship above the waterline that are subjected to a corrosive environment,” Spaulding said. “Navy warships are some of the most sophisticated machines globally, and the nature of combat systems with compound curvature and multiple angles, combined with composite materials, antennas and sensors create complex geometries. If our technology can be demonstrated on combat systems, then it will have applicability on other parts of the ship that are less complex.”

It has been noted that Aerial and NSWC PHD are seeking additional partners or collaborators to work on the project. For more information, contact Jaeger at alan.w.jaeger@navy.mil or Spaulding at chuck@aerialalchemy.com.

Previous Projects

Not the first time Aerial has worked under a CRADA with NSWC PDH, back in June 2018, the two operated under another agreement to research how digital twins could be used. To start, researchers produced a digital twin of the research vessel “Independence” in addition to other ships in the U.S.S. Theodore Roosevelt strike group.

Prior to the agreement, the Navy was still commonly using the Consolidated Afloat Networks and Enterprise Services program, which aims to move all its ships toward a common IT baseline. However, because every ship is different, the move to a digital twin approach has developers exploring more accurate models of vessels in a real-world network at any particular point in time.

To create a digital twin, Aerial first worked to define the appropriate amount of remote-sensing technologies that would be needed to design a purpose-built unmanned aerial system. According to reports, Aerial used LiDAR and hyperspectral imaging, which is able to analyze information collected from across an electromagnetic spectrum.

The technology can also detect corrosion, as paint reflects radiation differently if there is underlying rust.

Scans from drones and onboard photogrammetry were used as well, to create a time-based, geotagged, metadata-dense models of the Independence. The Federal Laboratory Consortium for Technology Transfer reports that these models are much more actionable datasets which can lead to a reduction in maintenance costs and human error because engineers are now able to make decisions prior to failure by degradation.

Once collected, the information is collected for operation in a commercial cloud environment where maintenance engineers (both on and offshore) can develop solutions.

The project was part of NSWC’s Naval Innovative Science and Engineering research on technologies look to advance the future of in-service engineering. The Federal Technology Transfer Act of 1986 allows warfare centers and research laboratories to collaborate with industry and academic in research, engineering and technology development.

Two years later in 2020, the Navy announced that it had begun exploring the use of the digital twins to help combat shipboard repairs and maintenance services. Comprised of IT networks the technology is reported to successfully identify damage, corrosion and alignment issues more quickly. The practice also aids crews in being more proactive about the vessel’s maintenance prior to docking at the port.

More recently, this month, a team working at the Fleet Readiness Center East in Cherry Point, North Carolina, examined new possibilities for quickly and accurately detecting corrosion and preventing its spread on Navy- and Corps-owned military aircraft.

FRCE, located within the Marine Corps Air Station, is touted as North Carolina’s largest maintenance, repair, overhaul and technical services provider, with more than 4,000 civilian, military and contract workers. Its annual revenue exceeds $1 billion.

To better mitigate corrosion and costly repairs, the team at FRCE started working under an F-35 Lighting II program, where members observed the demonstration of a tool created to help identify corrosion on a variety of aircraft coatings and help prevent its spread.

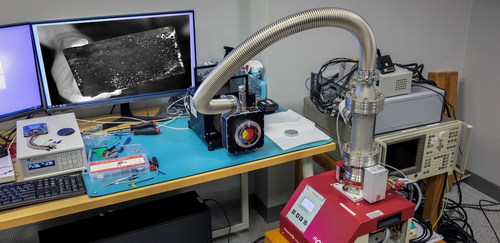

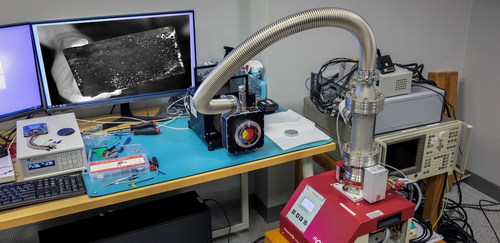

Through the use of a mid-wave infrared camera to visually penetrate aircraft coatings and record images of the surface below, the Grey Gecko Real-Time Inspection Tool, or GRIT system, aims to reliably identify corrosion and help facilitate faster, less objective corrosion inspections that reduce corrosion growth and associated costs, and increase aircraft availability.

Grey Gecko estimates use of the GRIT for non-destructive inspection can reduce aircraft downtime caused by corrosion by up to 25% and reduce the inspection manpower requirement by more than 50% in some applications.

Although the GRIT demonstration was organized by the F-35 program, the exercise was reported to have fallen right in line with the ATI Team’s mission of developing solutions for the multiple aircraft supported by FRCE. Moving forward, the F-35 team plans to conduct additional work with the ATI Team to observe additional technologies that have potential benefit for both F-35 and other fleet support teams and maintenance, repair and overhaul operations.

Tagged categories: Coating inspection; Corrosion; Corrosion protection; Digital tools; Drones; Inspection; Maintenance programs; Marine; Quality control; Quality Control; Research and development; Ships and vessels; Technology; Tools & Equipment; U.S. Navy