Researchers Look at Novel Spraying Method

THURSDAY, MAY 7, 2020

Researchers at the University of Bayreuth, in Bayreuth, Germany, are reportedly working on a novel spraying method, Powder Aerosol Deposition, which they say enables the production of ceramic coatings at room temperature.

Typically, according to the researchers, ceramic coatings production has only been possible by means of sintering techniques, which require temperatures of more than 1,000 degrees C.

Engineering scientists under the direction of professor Ralf Moos are working on the development of the technology.

The Research

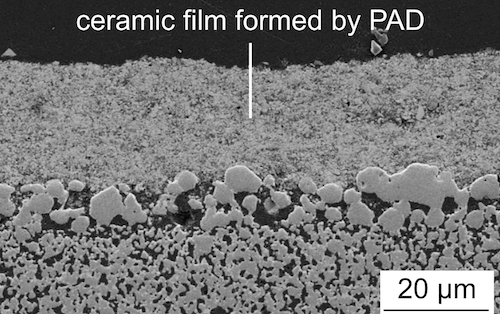

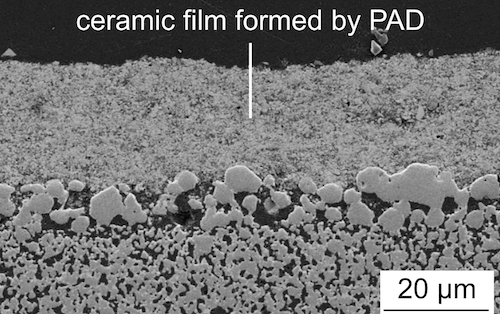

According to the University, with PAD, dense ceramic films can be applied to different types of materials such as steel, glass, silicon or plastic.

|

| Jörg Exner |

|

Researchers at the University of Bayreuth, in Bayreuth, Germany, are reportedly working on a novel spraying method, Powder Aerosol Deposition, which they say enables the production of ceramic coatings at room temperature. |

To achieve this, a dry ceramic powder is first converted into an aerosol—a mixture of gas and solid particles—with the aid of a carrier gas. The aerosol is then transported into a vacuum chamber and accelerated to several 100 meters per second through a nozzle and directed onto the material to be coated.

On impact, the tiny ceramic particles fracture and the resulting fragments—only a few nanometers in size—form tightly adhering, dense coatings with a thickness of between 1 and 100 micrometers.

"Thanks to their dense microstructure, the coatings already exhibit excellent mechanical properties even directly after the deposition,” said Jörg Exner, first author of the study, who was a driving force in the research work on PAD at the University.

“They are extraordinarily hard and have good chemical resistance.”

The researchers note, however, that some properties such as electrical conductivity need further steps, because the impact of the ceramic particles on the materials causes structural defects in the resulting fragments. This not only affects electrical conductivity, but also other functional properties.

"By a thermal post-treatment, or so-called tempering, these defects can be almost completely eliminated,” Exner said.

“We have been able to show that the required temperatures are generally much lower than for conventional sintering. The avoidance of these extremely high temperatures is what makes PAD so attractive. It therefore remains true: This technology offers very high industrial potential, especially where high-quality ceramic coatings are required.”

Tagged categories: Aerosol coatings; Ceramic coatings; Coatings Technology; Coatings Technology; Research and development