Ultrathin Coating Hides Heat from Infrared Cameras

WEDNESDAY, JANUARY 15, 2020

At the University of Wisconsin–Madison, engineers have recently announced the development of a new ultrathin coating, reported to camouflage heat when viewed through infrared technology.

The research findings have since been published in the Proceedings of the National Academy of Sciences by Mikhail Kats, a UW–Madison professor of electrical and computer engineering, his group of UW-Madison engineers and other collaborators from Purdue University, Harvard University, Massachusetts Institute of Technology and Brookhaven National Laboratory.

Coatings Technology

In using samarium nickel oxide, engineers were able to craft the new ultrathin coating, which Kats reports could have applications in heat transfer, camouflage and even clothing as to protect personal privacy as infrared cameras become more available to consumers.

|

| University of Wisconsin-Madison |

|

At the University of Wisconsin–Madison, engineers have recently announced the development of a new ultrathin coating, reported to camouflage heat when viewed through infrared technology. |

“This is the first time temperature and thermal light emission have been decoupled in a solid object,” said Kats. “We built a coating that ‘breaks’ the relationship between temperature and thermal radiation in a very particular way.”

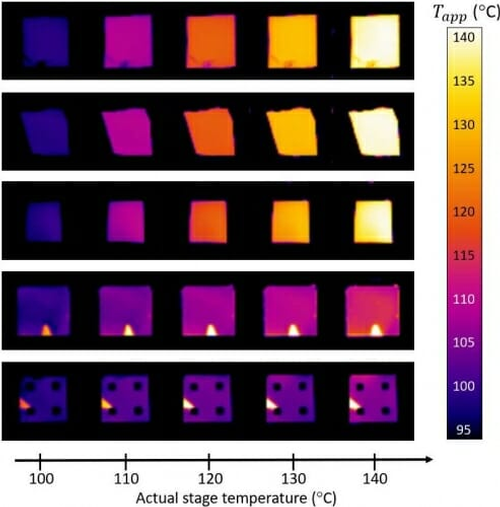

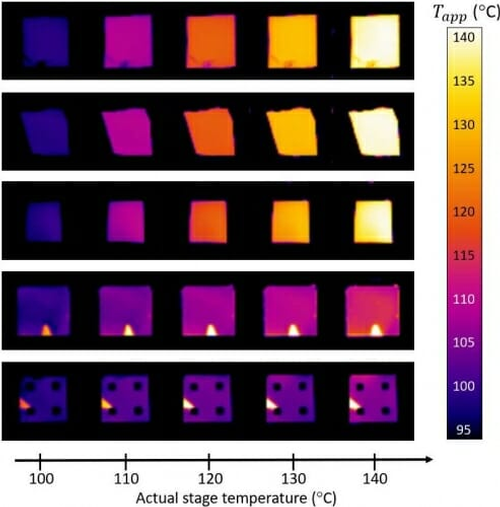

While the temperature range for which power from the thermal radiation emitted by the coating stays the same only works between 105-135 C, the coating itself still emits a fixed amount of thermal radiation regardless of its temperature.

Alireza Shahsafi, a doctoral student in Kats’ lab and one of the lead authors of the study, reports that this is because of the coating’s emissivity—the degree to which a given material will emit light at a given temperature—will go down with temperature and cancels out its intrinsic radiation.

To demonstrate the coatings efficiency, Shahsafi and Patrick Roney led engineers in experimental work that involved suspending a coated piece of sapphire and an uncoated reference piece alongside a heater so that a portion of each sample was touching the heater, while the rest remained suspended in cool air.

When viewed under an infrared camera, the coated sapphire’s thermal image remained largely uniform, however, the reference piece revealed a distinct temperature gradient: from deep blue to pink, red, orange and nearly white. Several other students in Kats’ group characterized the coating through microscopy and other methods.

“If we could cover the outside of clothing or even a vehicle with a coating of this type, an infrared camera would have a harder time distinguishing what is underneath,” said Shahsafi.

“View it as an infrared privacy shield. The effect relies on changes in the optical properties of our coating due to a change in temperature. Thus, the thermal radiation of the surface is dramatically changed and can confuse an infrared camera.”

In certifying the project’s success, Purdue collaborator Shriram Ramanathan’s group synthesized the samarium nickel oxide and performed detailed materials characterization, while MIT and Brookhaven National Laboratory groups used a particle-accelerating synchrotron’s bright light to study the coating’s atomic-level behavior.

Research for the project was supported by grants from the Office of Naval Research.

In addition to previously mentioned leaders in the project, other authors on the PNAS paper include Yuzhe Xiao, Chenghao Wan, Raymond Wambold, Jad Salman and Zhaoning Yu of UW–Madison, You Zhou of Harvard, Zhen Zhang of Purdue, Jiarui Li and Riccardo Comin of MIT, and Jerzy Sadowski of Brookhaven National Laboratory.

Tagged categories: Brookhaven National Laboratory; Coating chemistry; Coating Materials; Coating Materials; Coatings; Coatings technology; Coatings Technology; Colleges and Universities; Engineers; Harvard University; Massachusetts Institute of Technology; Purdue University; Research; Research and development; U.S. Naval Research Lab; University of Wisconsin–Madison