MIT Team at Work on Nuclear Cladding Coating

MONDAY, MAY 1, 2017

A new research project at the Massachusetts Institute of Technology has the goal of identifying the ideal coating for fuel cladding in nuclear reactors.

A team led by nuclear science and engineering professor Michael Short will take on the three-year job, which is funded by Exelon Generation, the country’s largest operator of nuclear power plants. The goal is to evaluate potential coatings for fuel cladding in light water reactors, and identify the best coating to address a number of issues that currently exist in the field.

|

| Susan Young, courtesy of MIT |

|

A team led by nuclear science and engineering professor Michael Short (pictured) has the goal of identifying the ideal coating for fuel cladding in nuclear reactors. |

Light water reactors include boiling water reactors and pressurized water reactors, and comprise all of the 99 operational nuclear power plants in the United States, as well as four that are under construction in the country.

Cladding Issues

Fuel cladding is the solid layer that surrounds nuclear fuel rods, acting as a barrier between the fuel rods and the coolant. It is generally made of zirconium alloy, known as zircaloy. While research is ongoing into whether there might be a better material for the construction of the cladding, the project at hand looks at how to better protect currently existing zircaloy cladding through coatings.

|

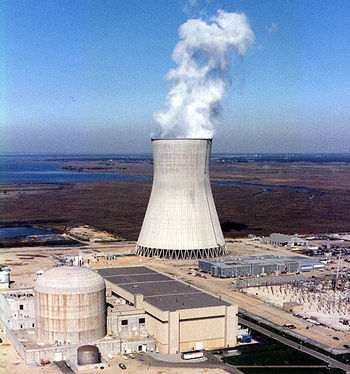

| Nuclear Regulatory Commission, public domain |

|

Light water reactors include boiling water reactors and pressurized water reactors, and comprise all of the 99 operational nuclear power plants in the United States, including Hope Creek (pictured), in New Jersey. |

The MIT team notes that four major issues tend to come up with regard to zircaloy cladding. Grid-to-rod fretting can wear through the cladding, the engineers say. Porous corrosion deposits can also develop, the cladding can absorb hydrogen, and a “boiling crisis” can occur, changing the nature of the coolant boiling and leading to suboptimal heat transfer.

The research group is looking to identify coatings and surface modifications that will address all of the problems, limiting deposits, preventing grid-to-rod fretting, and limiting the possibility of phase change by maximizing critical heat flux.

About the Team

The team, which will work with Westinghouse Electric on the project, consists of Short and professors Bilge Yildiz, Matteo Bucci and Evelyn Wang, working in partnership with the MIT Nuclear Reactor Laboratory.

The goal is to have the ideal fuel-cladding coating ready and commercialized in 2019, a time frame that MIT notes is greatly accelerated in comparison with most nuclear reactor materials developments, which can take more than a decade.

Tagged categories: Coating chemistry; Coating Materials; Coating Materials; Colleges and Universities; Massachusetts Institute of Technology; Nuclear Power Plants; Power Plants; Research and development