Material Measures the ‘Mood’ of Structures

TUESDAY, NOVEMBER 29, 2016

Mood rings may have been a fleeting fad of the 1970s, but researchers at Vanderbilt University are using the basic concept as a means of detecting damage in failing infrastructure before it becomes critical.

An interdisciplinary research team at Vanderbilt’s Laboratory for Systems Integrity and Reliability (LASIR) is credited with developing the new sensing system, which incorporates nanoparticles in a clear polymer resin, the school announced Nov. 21.

The end result is “a smart material that changes color when it is damaged or about to fail, what I call a ‘mood ring material,’” explains civil engineering doctoral student Cole Brubaker.

Sending a Clear Signal

Smart sensing technologies are a hot new field in civil, mechanical and aerospace engineering, according to the university, but these technologies often rely on networks of physical sensors attached to the structures they monitor. These methods are reported to be expensive and involve high power and data processing requirements.

The LASIR researchers’ technique seems to offer an efficient and cost-effective alternative. Their method incorporates fluorescent nanoparticles that react to stress by changing their optical properties, into the material itself.

“Currently, there are two ways to keep everything from bridges to aircraft safe,” says Douglas Adams, LASIR director and Daniel F. Flowers Professor of civil and environmental engineering.

“One is to send people out to look at them with a flashlight. The problem with this is that it is labor-intensive and the people can’t see very small cracks when they form,” he explains.

“The other is to install elaborate sensor networks that constantly look for small cracks and detect them before they grow too large,” he adds.

“The problem is that these networks are very expensive and, in the case of aircraft, add a lot of weight. So we need to somehow change the materials we are using so they illuminate these tiny cracks.”

The team determined that adding a tiny concentration of special nanoparticles (1 to 5 percent by weight) to an optically clear polymer matrix produces a distinctive light signature that changes as the material is subjected to compressive and tensile loads.

White Light Quantum Dots

The Vanderbilt team is not the only group working with nanoparticles to create smart materials, but they do have the advantage of working with a particular type of nanoparticle called a white light quantum dot, the university says.

These quantum dots, developed in 2005 in the laboratory of Sandra Rosenthal, Vanderbilt’s Jack and Pamela Egan Professor of Chemistry, are unique because they emit white light where other quantum dots only emit light at specific wavelengths.

“White light quantum dots have very unique optical properties compared with other nanoparticles,” says Talitha Frecker, a chemistry graduate student participating in the study. “The white light fluorescence is a surface phenomenon.”

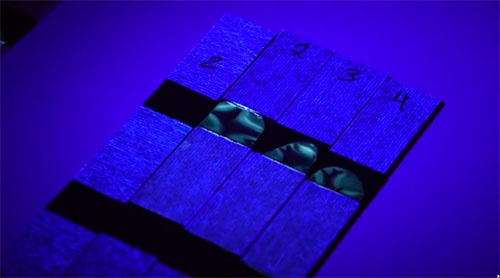

|

| Photos: Vanderbilt University |

|

The research team intends for their material to essentially tell an inspector when a structure like a bridge has been experiencing unusual stresses or a crack has begun before a more serious problem occurs. |

Adams reportedly saw the quantum dots' potential for creating smart materials when he came to the university in 2013, noting that when added into a material, the nanoparticles observe and react to what is going on around them.

Preliminary Studies

The team’s initial studies have involved coating fiberglass and aluminum strips with a polymer coating containing white light quantum dots and subjecting them to varying degrees of external load. They observed that the intensity of the emission spectrum produced by the quantum dots decreases as the load increases.

“The mechanism is still a bit unclear, but we have demonstrated that entrapping these quantum dots in ultra-thin polymer films on metal surfaces can provide advance warning when the underlying metal is about to sustain physical or chemical damage,” says Professor of Chemical and Biomolecular Engineering Kane Jennings, who is participating in the project along with doctoral student Ian Njoroge.

The researchers theorize that the quantum dots emit light in a broad spectrum because more than 80 percent of the atoms lie on the surface. They also know that the bonds between the surface atoms and molecules surrounding them plays a critical role.

“The end result is that the strength of the quantum dot emissions gives us a permanent record of the level of stress that a material has experienced,” says Brubaker.

|

|

"The end result is that the strength of the quantum dot emissions gives us a permanent record of the level of stress that a material has experienced,” says Cole Brubaker, a doctoral student in civil engineering who is part of the interdisciplinary research team. |

Through this preliminary research, the team verified that the material can act as a new kind of strain gauge that permanently records the cumulative amount of stress that the material to which it is applied experiences, the school says.

Continuing Work

Because the engineers have kept the loads relatively modest, under 1,250 pounds, in these early stages of their studies, the researchers know that things will get more complicated as they ramp up the stresses they are applying. They also expect to encounter additional challenges and problems to solve.

“There is a lot we have to learn before we can create a smart material that is ready for real world applications, but all the signs are positive,” says Adams.

“Some of our commercial partners are very interested so there is a good chance that it will be adopted if it performs as well as we think it will.”

The team’s initial work was published in the Proceedings of the SPIE Conference on Sensors and Smart Structures Technologies for Civil, Mechanical and Aerospace Systems.

The research is being supported by a U.S. Office of Naval Research grant.

Tagged categories: Coating Materials; Coatings Technology; Colleges and Universities; Infrastructure; Nano and hybrid coatings; Nanotechnology; Polymers; Research and development; Resins; Safety